Machine Vision Solution

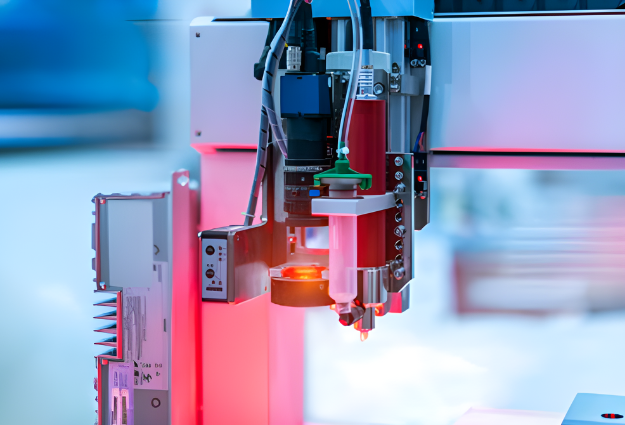

Our Machine Vision Solution utilizes advanced imaging technology and artificial intelligence algorithms to automate visual inspections, quality control, and process optimization. By detecting defects, analyzing images, and providing actionable insights, we help you achieve higher product quality and operational efficiency.

Why Machine Vision Solution

-

1. Improved Quality Control in Manufacturing:

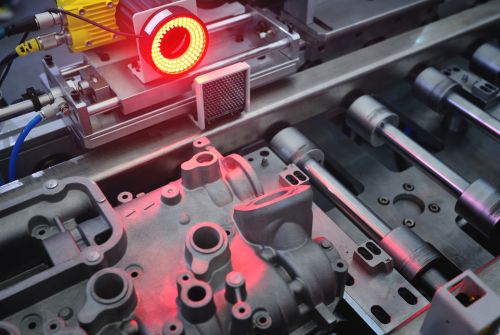

• Enhanced quality control processes through automated visual inspection.

• Consistent and accurate identification of defects and anomalies.

• Reduction in product defects, rework, and customer complaints. -

2. Error Reduction in Manual Inspection:

•Minimization of errors associated with manual inspection processes.

• Elimination of human subjectivity and fatigue.

• Improved accuracy and reliability of inspection results. -

3. Faster and Accurate Defect Detection:

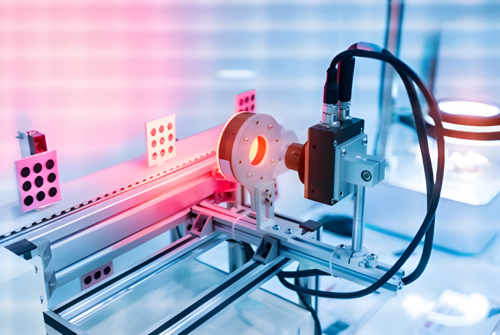

• Increased speed and efficiency in defect detection.

• Real-time identification of defects during the production process.

• Prompt response and mitigation of quality issues. -

4. Integration of Machine Vision Systems:

• Seamless integration of machine vision systems into existing processes.

• Compatibility with production lines and equipment.

• Streamlined workflows and optimized performance. -

5. Cost Savings and Efficiency:

• Reduction in production costs associated with defects and rework.

• Improved productivity and throughput.

• Potential for automated sorting and rejection of defective products.

features of Machine Vision Solution

Experience Advanced Quality Control with Our Cutting-Edge Machine Vision Solution

1.Automated Visual Inspections and Defect Detection:

2. Image Analysis and Classification:

3. Real-Time Monitoring and Alerts:

4.Seamless Integration with Production Lines and Control Systems:

5.Customizable Inspection Criteria and Rules:

By choosing our Machine Vision Solution, you gain a competitive edge with improved quality control accuracy, reduced errors, increased productivity, and enhanced customer satisfaction. Experience the power of advanced image analysis, real-time monitoring, seamless integration, and customizable inspection capabilities.

USP: Quality. Efficiency. Adaptability.

USP

By choosing our Machine Vision Solution, you gain a competitive edge with improved quality control accuracy, reduced errors, increased productivity, and enhanced customer satisfaction. Experience the power of advanced image analysis, real-time monitoring, seamless integration, and customizable inspection capabilities.